The main coil of the product is already on the PCB board and does not need to be wound outside. It is convenient for enthusiasts to install. It is efficient and beautiful. It is a new design. This Tesla coil is safe and does not cause electrocution to people. The electric arc can only be used to light the lamp in space, and it can be used for student experiments, course design, etc. All the devices are on-line, there is no fixture, and there are few devices, and the success rate is high, which is suitable for beginners.

Input voltage: dc4.5v, please do not exceed 4.5v, otherwise it will burn out

Input current: 180ma-380ma

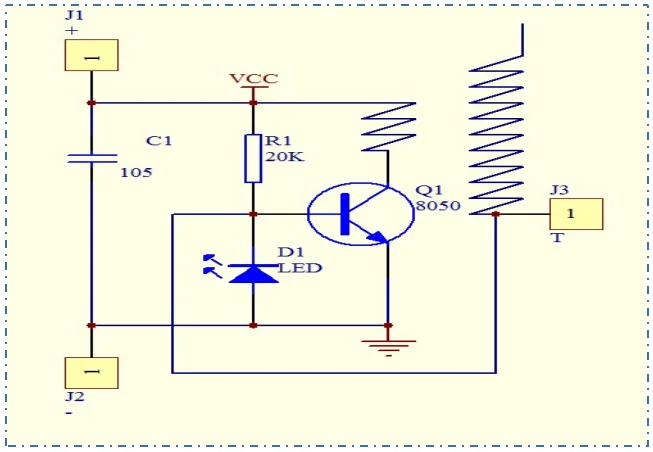

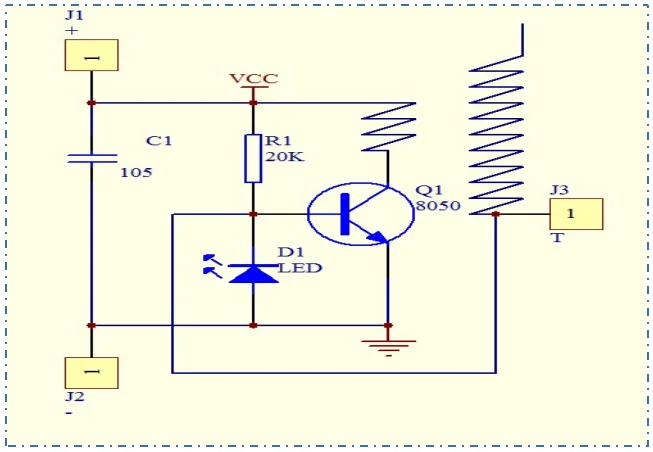

Schematic diagram:

Secondary coil parameters:

Enamel wire diameter: 0.13mm (with color 0.15mm)

Frame material: PVC pipe

Frame outer diameter: 2cm

Frame height: about 4 cm

Number of laps: 200 laps

Winding direction: Bottom-up direction

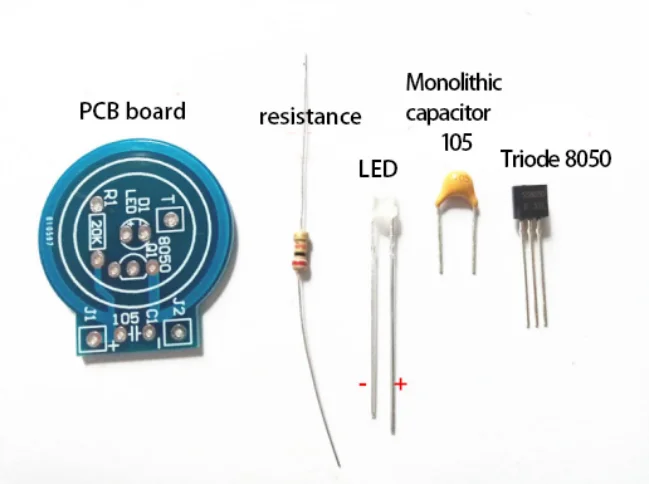

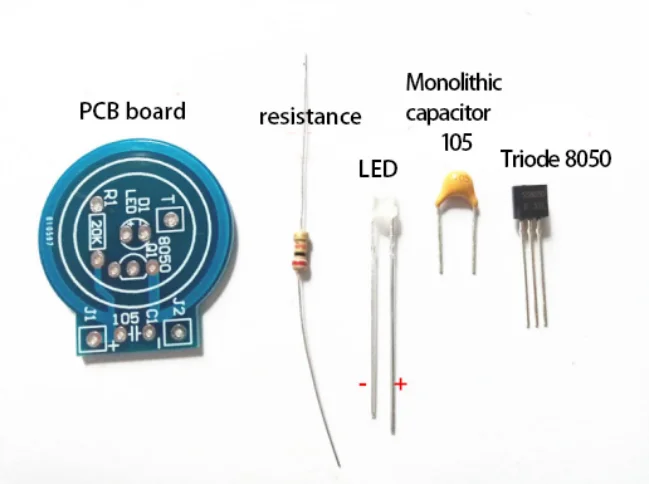

The package included:

1 x PCB board

1 x Secondary coil

1 x AA battery box with switch

1×105 Monolithic

1×8050 Transistor

1 x20k resistance

1 x3mm led

Small battery version tesla welding steps

1. Know the ingredients

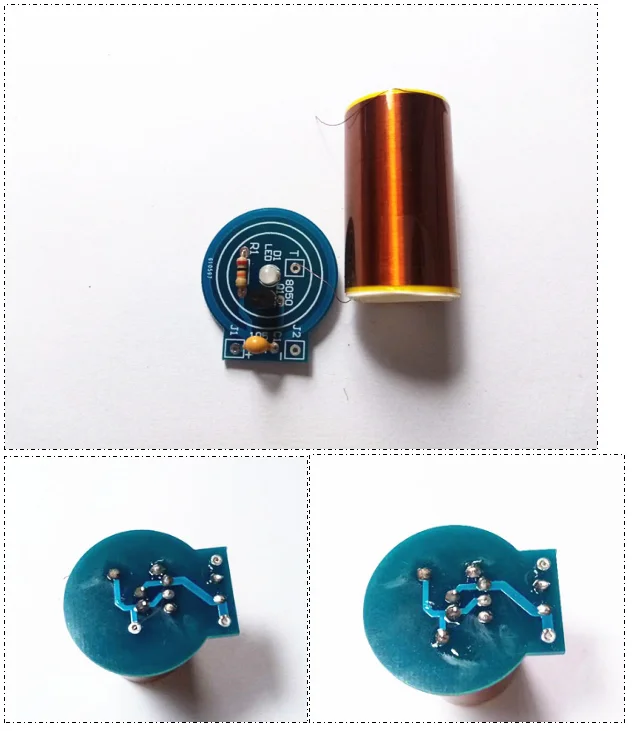

2. The shortest component to be welded: resistance

3. For LED welding lights, the long leg is the positive pole and the short leg is the negative pole

4. Welding the 8050 triangle, pay attention to the silk screen on the kanban, flat to flat

5. 105 Monolithic welding capacitor, no polarity

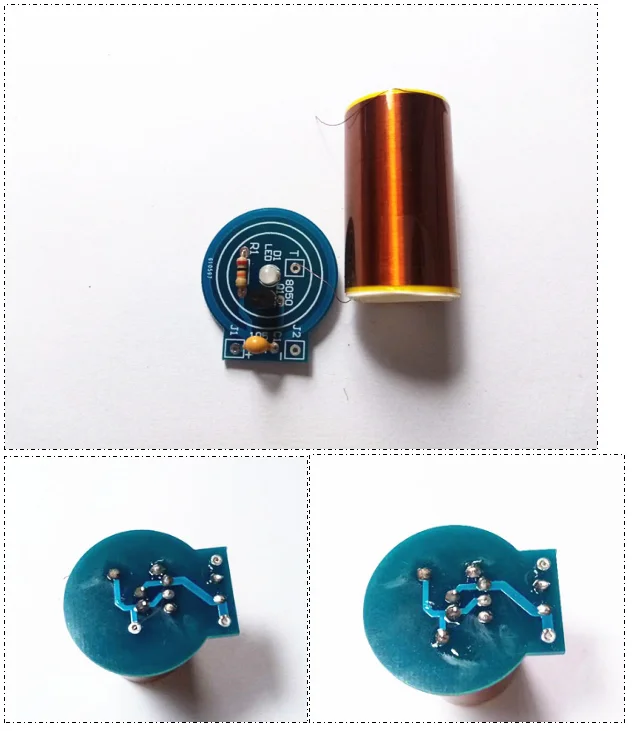

6. Deal with secondary coil

The primary coil is integrated on the PCB board, no soldering is needed, only the secondary coil is soldered.

The secondary coil is led by two copper wires, scrape the insulated paint at one end of the copper wire to expose the white copper wire. (If you find the end of the secondary coil pvc pipe with less white space, scrape the end with less white space. If both ends are almost white or there is no white space, just choose one end of the copper wire and scrape) The wire can not come out for a long time. Otherwise the coil will be useless!

Be careful not to burn it with fire, it is better to scrape with a blade, scrape gently, do not scratch, do not scratch, and do not pull out for too long!

7. To solder the secondary coil, insert the downward end of the secondary coil into the T-hole of the PCB board, and then solder it.

8. Welding the battery box and testing

After the secondary coil is welded, weld the battery box on. The red wire is welded to the positive electrode and the black wire is welded to the negative electrode. After welding, install the battery and test it. The LED light on the board is on, and the light of the bulb is close to it. You can also use an energy-saving lamp to close the test. It is about 3w to 5w. If it can also be bright, the welding is successful.

9. Fixed coil

After the test is successful, the secondary coil can be fixed with glue. It can be supplied with double-sided adhesive, or 502 adhesive. When fixing, be careful not to break the lead of the secondary coil!

10. This baby contains simple components, easy welding, safe battery power supply. This is Tesla’s entry-level kit. I wish you all successful welding!

AC Pump

AC Pump Air Pump

Air Pump DC Solar Pump

DC Solar Pump Brushless Motor

Brushless Motor Stepper Motor

Stepper Motor Servo Motors

Servo Motors AC Synchronous Motor

AC Synchronous Motor Linear Actuator Motor

Linear Actuator Motor

Audio Amplifier

Audio Amplifier Convertor Boards

Convertor Boards Microcontroller

Microcontroller Motor Driver

Motor Driver Relay

Relay Voltage Regulator

Voltage Regulator

Charger & Power Supply

Charger & Power Supply Battery Holder Case

Battery Holder Case Li-Po Battery

Li-Po Battery Lithium iron phosphate battery

Lithium iron phosphate battery Solar Panel & Inverter

Solar Panel & Inverter

3D Printer Parts

3D Printer Parts Body Chassis

Body Chassis CNC Parts

CNC Parts Gears – Gearboxes

Gears – Gearboxes Hub – Motor – Wheel Coupler

Hub – Motor – Wheel Coupler Motor Holders

Motor Holders Enclosures & Cases

Enclosures & Cases Wheels – Shafts

Wheels – Shafts

Reviews

There are no reviews yet.